ELECTRONIC POTTING & ENCAPSULATION MATERIALS

Electrical potting compounds Materials are designed to insulate and protect electrical and electronic components from the application and environmental stresses.

Maxtech Electronics potting and encapsulating compounds for many applications, including transformers, transducers, motors, stators, capacitors, controllers, the PCBs, protecting printed circuit boards, electronic devices, various modules, automotive module, LED Power, LED Lamps, Lights, driver modules, Solar panel junction box, EV charging column module, Lithium battery pack, Capacitor banks, Magnetic induction coils, Power inverters, Rigid Strips, display module, LCD, photoelectric sensor, intelligent water meter and other optoelectronics display products, the electric motor, electric tools, reactors, meters sensors, high-temperature wire harness, automotive electronics, and so on.

Maxtech electronic potting and encapsulating compounds are formulated for high performance in nearly any application. Our chemists and developers can also create custom formulations to your exact specifications. All custom compounds are extensively tested to ensure you get the product you need, capable of handling whatever stresses it could potentially encounter in its application.

Maxtech offers a comprehensive selection of epoxy, silicone, and polyurethane potting compounds to meet the most demanding specifications.

• Silicone Potting and Encapsulation Compounds

• Epoxy Potting Compound

• Polyurethane Potting Compound

• Thermally Conductive Encapsulants & Potting For Electronics

• Dielectric Silicone Gel Potting Materials

• Conformal Coatings Materials

Silicone Potting and Encapsulation Compounds

Maxtech Flexible Silicone Potting and Encapsulation Compound is a two-component condensation curing system, was created for potting and encapsulation applications where it is not possible to use an addition-cured silicone. The system requires only air for complete cross-linking. In contrast to addition-cured systems, it does not contain any substrates that could suppress the cure.

Silicone Potting and encapsulating compounds are used to protect electrical components and applications from external threats, such as water, moisture, chemicals, shock, and vibrations. Potting and encapsulating compounds are liquid epoxy resins, urethanes, or silicones made from two compounds to fill voids and protect fragile electrical components, devices, and circuitry from exposure to harmful elements.

Maxtech SI8230 Two Component Thermally Conductive Flame Retardant Silicone Potting Compounds Adhesive

Color: White/Black /Gray Color

Packaging: Part A:20 KG/Drum, Part B:20 KG/Drum

The Ratio of A and B: Part A : Part B =1 :1

Operation Time: 50±10mins

Cure condition: 25℃/3-5 hr or 80℃/ 30mins

Hardness: 55±5 Shore A

Thermal conductivity: 0. 65±0.03W/mK

Application temperature: - 60 ∽ 200 ℃

Shelf Life: 12 months

Application: ●Used for encapsulation of various modules, automotive module, LED Power driver modules, Solar panel junction box, EV charging column module, Lithium battery pack, Capacitor banks, Magnetic induction coils, Power inverters, etc.

Maxtech SI8230-1 Low stress Soft Flame Retardant Silicone Potting Adhesive

Color: Drak Gray elastomer

Packaging: Part A:20 KG/Drum, Part B:20 KG/Drum

The Ratio of A and B: Part A : Part B =1 :1

Operation Time: 15±5mins

Cure condition: 25℃/4 hr or 80℃/ 30mins

Hardness: 35±5 Shore A

Thermal conductivity: 0. 6W/mK

Application temperature: - 60 ∽ 200 ℃

Shelf Life: 12 months

Application: ●Used for encapsulation of various modules, automotive module, LED Power driver modules, Solar panel junction box, EV charging column module, Lithium battery pack, Capacitor banks, Magnetic induction coils, Power inverters, etc.

Maxtech SI8230-3 Two Component Low Stress Silicone Gel Encapsulant

Color: Drak Gray to Black elastomer

Packaging: Part A:20 KG/Drum, Part B:20 KG/Drum

The Ratio of A and B: Part A : Part B =1 :1

Operation Time: 40±10mins

Cure condition: 25℃/4 hr or 80℃/ 30mins

Hardness: 35±5 Shore A

Thermal conductivity: 0.75W/mK

Application temperature: - 60 ∽ 260 ℃

Shelf Life: 12 months

Application: ●Used for encapsulation of various modules, automotive module, LED Power driver modules, Solar panel junction box, EV charging column module, Lithium battery pack, Capacitor banks, Magnetic induction coils, Power inverters, etc.

Maxtech SI8230ZN High Thermal Conductivity Flame Retardant Silicone Potting Adhesive

Color: Gray elastomer

Packaging: Part A:20 KG/Drum, Part B:20 KG/Drum

The Ratio of A and B: Part A : Part B =1 :1

Operation Time: 40±10mins

Cure condition: 25℃/8 hr or 70℃/ 50mins, 80℃/ 30mins

Hardness: 50±5 Shore A

Thermal conductivity: 1..2W/mK

Application temperature: - 60 ∽ 260 ℃

Shelf Life: 12 months

Application: ●Used for encapsulation of various modules, automotive module, LED Power driver modules, Solar panel junction box, EV charging column module, Lithium battery pack, Capacitor banks, Magnetic induction coils, Power inverters, etc.

Maxtech SI8250 Clear Optical grade high purity two component liquid silicone potting encapsulation for optical device modules

Color: Clear/Transparent

Packaging: Part A: 0.5kg/Pot, Part B:0.5kg/Pot; Part A:5kg/Pot, Part B:5kg/Pot.

The Ratio of A and B: Part A : Part B =1 :1

Operation Time: 100mins

Cure condition: 25℃/24 hr or 100℃/ 60mins, or 100mins/3hrs ( with better bonding)

Hardness: 50 Shore A

Tensile Strength: 5.5Mp

Application temperature: - 60 ∽ 260 ℃

Shelf Life: 12 months

Application: ●Designed for the manufacture of optical device modules, and can be used for injection molding an optical lens and an optical wave guide coupling reduces scattering loss.

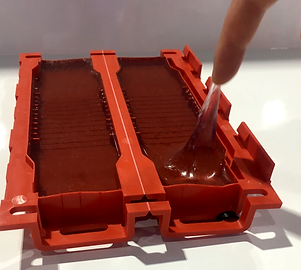

Maxtech SI8295 Two Component RTV / Heat Cured Silicone Potting Adhesive

Color: Red Elastomer

Packaging: Part A: 5kg/Drum, Part B:0.5kg/Pot;

The Ratio of A and B: Part A : Part B =10:1

Operation Time: 50-60mins

Cure condition: 100℃/ 60mins

Hardness: 45±5 Shore A

Thermal conductivity: 0.45W/mK

Application temperature: - 60 ∽ 260 ℃

Shelf Life: 12 months

Application: ●Designed for ●The stator of the generator; ●Power vacuum circuit breaker; ●Magnetic induction coil; ceramic electrode; ●Automotive electronics, power control module; ●Photovoltaic junction box, photovoltaic inverter

Maxtech SI8295-2 Two Component Red Color RTV / Heat Cured Silicone Potting Sealant

Color: Red Elastomer

Packaging: Part A: 5kg/Drum, Part B:0.5kg/Pot;

The Ratio of A and B: Part A : Part B =10:1

Operation Time: 30-50mins

Cure condition: 25℃/8 hrs or 80℃/ 30mins

Hardness: 40±5 Shore A

Thermal conductivity: 0.6W/mK

Application temperature: - 60 ∽ 260 ℃

Shelf Life: 12 months

Application: ●Designed for ●The stator of the generator; ●Power vacuum circuit breaker; ●Magnetic induction coil; ceramic electrode; ●Automotive electronics, power control module; ●Photovoltaic junction box, photovoltaic inverter

Maxtech SI8300 General Use Two Component Silicone Encapsulants & Potting Compounds For Electronic

Color: White / Red Elastomer

Packaging: Part A: 10kg/Drum, Part B:1kg/Pot;

The Ratio of A and B: Part A : Part B =10:1

Operation Time: 60mins

Cure condition: 25℃/6 hrs or 80℃/ 30mins

Hardness: 55Shore A

Thermal conductivity: 0.8W/mK

Application temperature: - 60 ∽ 260 ℃

Shelf Life: 12 months

Application: ●Designed for ●The stator of the generator; ●Power vacuum circuit breaker; ●Magnetic induction coil; ceramic electrode; ●Automotive electronics, power control module; ●Photovoltaic junction box, photovoltaic inverter

Maxtech SI8125 High Performance Two Component Silicone Encapsulants & Potting Compounds Adhesive For Electronic

Color: Transparent/ Matte White/ White / Black Elastomer

Packaging: Part A: 10kg/Drum, Part B:1kg/Pot;

The Ratio of A and B: Part A : Part B =10:1

Operation Time:40mins

Cure condition: 70~180mins

Hardness: 12~28 Shore A

Thermal conductivity: 0W/mK

Application temperature: - 60 ∽ 260 ℃

Shelf Life: 12 months

Application: ●Used for Automotive electronics, modules like Power control modules, Solar modules, Junction box, LED spotlight, Wall washer light, Strip lights, LED fluorescent lamp, etc.

Maxtech SI8300R Two Component Red Color Silicone Encapsulants & Potting Compounds For Electronic

Color: / Red Elastomer

Packaging: Part A: 10kg/Drum, Part B:1kg/Pot;

The Ratio of A and B: Part A : Part B =10:1

Operation Time: 30mins

Cure condition: 25℃/6 hrs or 80℃/ 30mins

Hardness: 45Shore A

Thermal conductivity: 0.8W/mK

Application temperature: - 60 ∽ 260 ℃

Shelf Life: 12 months

Application: ●Designed for ●The stator of the generator; ●Power vacuum circuit breaker; ●Magnetic induction coil; ceramic electrode; ●Automotive electronics, power control module; ●Photovoltaic junction box, photovoltaic inverter

Dielectric Silicone Gel Potting Materials

Color: Clear

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/24hour, 80°C/30min

Needle penetration: 75

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector.

Color: Clear

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/6hour, 80°C/30min

Needle penetration: 110mm

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector.

Color: Clear

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/1hour, 80°C/15min

Needle penetration:110

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector.

Color: Light Blue / Transparent

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/8hour

Needle penetration:110

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector.

Color: Light Blue / Transparent

Packaging: Part A:10 KG/Pot, Part B:10 KG/Pot

The Ratio of A and B: Part A: Part B =1 :1

Cure condition:25°C/8hour

Needle penetration:110

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector,semiconductor devices.

Color: Transparent

Packaging: Part A:10 KG/Pot, Part B:10 KG/Pot

The Ratio of A and B: Part A: Part B =1 :1

Cure condition:25°C/10hours or 80 ℃/10mins

Needle penetration:80

Application: The cured gel is used in some medical mattresses, headrests, skin stickers, electric parts, IGBT modules, junction boxes, auto control, and inverter.

Maxtech SI8709 Two-component Transparent Liquid Self-healing Silicone Potting Gel For Electronic Component

Color: Light Blue / Transparent

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/8hour

Needle penetration:110

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector.

Maxtech SI8721 Two Component Flexible Medical Silicone Gel

Color: Transparent

Packaging: Part A:10 KG/Pot, Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/6hour, 120℃/15mins

Application:

● Suitable for sticking with skin, used for wound stickers, Scar sheet, eye patch and Nipple cover

● Also for filling the cover bag of headrest, seat lumbar pad etc

Color: Transparent

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/6hour or 80℃, 30mins

Needle penetration:100

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector.

Color: Transparent

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/24hour,80°C /30min

Needle penetration: 75 1/mm

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector.

Color: Transparent

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:80°C /30min

Hardness:10 Shore00

Application:

●Provide a glassy clear appearance to parts manufactured using it. The rubber is an excellent candidate to consider for the cost-efficient manufacture of highly transparent optical parts, with very low modulus.

●Rain-light sensors, camera systems, optical sensors.

Color: Transparent

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:23°C /2 hour; 80°C /30min; 120°C /15min

Hardness:60 Shore00

Application:

●Provide a glassy clear appearance to parts manufactured using it. The rubber is an excellent candidate to consider for cost-efficient manufacture of highly transparent optical parts, with very low modulus.

●Rain-light sensors, camera systems, optical sensors.

Color: Transparent/Black

Packaging: Part A:10 KG/Pot , Part B:10 KG/Pot

The Ratio of A and B: Part A : Part B =1 :1

Cure condition:25°C/20~60mins, 80℃/10mins

Hardness: 20~40 Shore 00

Application: Used for encapsulation of various modules, semi-conductor, IGBT, automotive ECU module, IC chip, weighing sensor, waterproof connector.

6M%60R%5DBJA(U.png)